Overview of Gas Fitting Tools and Equipment

Specialised tools and equipment are imperative to conduct gas fitting safely and effectively. This article from Padstow Plumbing will provide an overview of the key instruments used by our experienced technicians in Padstow, Sydney when installing, maintaining, and repairing gas systems.

As a reputable local plumbing company, we are fully licenced and equipped to handle all residential and commercial gas fitting jobs. Our technicians are thoroughly trained and consistently comply with SafeWork NSW and the Plumbing Code of Australia’s safety regulations.

The following sections will explore the wide variety of hand tools, power tools, protective gear, testing devices, and other essential gas fitting equipment. We’ll detail the roles of each tool and how our technicians skillfully use them for key gas fitting tasks such as sizing pipes, securing fittings, and ensuring robust connections and safety.

Common Hand Tools Used in Gas Fitting

Our seasoned Padstow Plumbing technicians follow a detailed management system, employing a suite of specialised hand tools for diverse gas fitting projects. Correct instruments are vital for precise pipe sizing, secure connections, and leak-proof installations in line with AS/NZS 5601 standards.

Some vital manual instruments we utilise daily include:

- Pipe Cutters: Available in a range of sizes suited for different pipe diameters, quality pipe cutters with sharp cutting wheels provide neat, straight cuts to prepare pipe ends for connections.

- Deburring Tools: Used after cutting to smooth pipe ends and remove any ridges or roughness that could impact sealing.

- Flare Nut Wrenches: Designed to grip and turn flare nuts when connecting fittings without causing damage. Appropriately sized to fit various nut dimensions.

- Tube Benders: Enable precise bending of metal gas pipes to route lines around obstacles and through confined areas.

- Torque Wrenches: Ensure flare nuts and other gas fitting components are tightened to recommended torque specs for secure, leak-free connections.

By using these and other specialised instruments properly, our technicians can complete quality gasfitting work safely, efficiently, and up to strict industry standards.

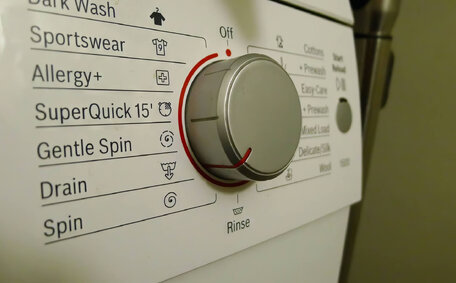

Wrenches

Wrenches are a crucial subset of gas fitting hand tools, enabling technicians to properly tighten or loosen fittings and connections. We use a range of specialised wrenches for safe, efficient gas work completion.

Key wrenches we rely on include:

- Flare Nut Wrenches: With openings sized to grip flare nut dimensions exactly, these allow tightening or loosening without slipping or damaging the nut surface. Available in imperial and metric sizes.

- Pipe Wrenches: Sturdy, adjustable heads grip and turn pipes of various diameters when fittings must be tightened or loosened in place.

- Basin Wrenches: Long handles and offset heads provide ideal leverage and angle access to tighten or loosen faucet nuts and connections located in confined sink spaces.

- Tubing Cutters: Compact, spring-loaded tools used one-handed to neatly cut copper refrigeration tubing and gas lines.

We meticulously maintain our wrench sets to ensure proper tool availability for all gas fitting jobs. We carefully use each tool, enabling safe and efficient installations and repairs.

Cutters

Utilising the proper cutters is a key aspect of safe and effective gas fitting procedures. At Padstow Plumbing, our technicians rely on quality pipe cutters designed specifically for use in gas installations.

Precision pipe cutting is crucial in gas fitting to ensure:

- Pipes are properly sized to deliver optimal gas flow

- Cut ends are straight, smooth, and free of burrs/obstructions

- Tight, leak-proof seals can be made when connecting fittings

Our technicians use manual wheel-type cutters for controlled, straight cuts on steel, copper, and plastic gas pipes. We take care to properly support pipes when cutting to avoid potential safety hazards.

Precise pipe sizing and cutting helps ensure open-flued gas heaters function safely. Incorrect sizing can cause negative pressure, leading to combustion products entering living areas.

By using the right cutting tools for the job and proper work methods, our technicians expertly cut and prepare pipe ends to facilitate secure, leak-free system installations that comply with all relevant Australian standards.

Power Tools for Gas Fitting Tasks

Besides essential hand tools, we employ various power tools for safe, efficient execution of diverse gas fitting tasks. These motorised instruments allow faster, more accurate work compared to manual methods alone.

Key gas fitting power tools we utilise include:

- Hammer Drills: Equipped with impact and rotation modes, these combine drilling and tapping functions for quickly boring holes through surfaces like brick and concrete to route gas pipes.

- Pipe Threaders: Allow rapid, precise threading of gas hoses ends to accept fittings. Much faster than manual threading.

- Metal Cut-Off Saws: Quickly cut through steel support beams, strut channel, and piping with intense rotary force.

We adhere stringently to all safety protocols when operating these and other motorised equipment. Our technicians wear appropriate protective gear, secure loose elements, and maintain full control over tools to prevent hazards.

Power tools allow us to complete complex gas fitting tasks safely with optimal efficiency. Our specialists choose the right instruments for each application and handle them skillfully thanks to extensive professional training and experience.

Drills

Drills are indispensable for tending to your gas fitting tools that allow our technicians to bore precise openings for routing pipes and installing fittings securely.

We utilise heavy-duty drill types designed for metal and pipe applications, including:

- Hammer Drills: With adjustable impact power, these combine drilling and hammering action for boring through brick, concrete, and other robust materials.

- Right-Angle Drills: Ideal for right hand drilling perpendicular openings in confined spaces, with compact heads positioned at 90-degree angles.

- Hole Saws: Outfitted on drill chucks, these circular cutters bore neat, accurately sized holes for inserting pipe fittings.

Our experts conduct gas fitting with proper support for materials to prevent hazards and ensure precise cutting. We create holes of precise diameters in walls and floors for inserting gas pipes per code requirements, allowing neat, inconspicuous system installations.

Saws

Saws are essential for accurately cutting various materials involved in gas systems. Our technicians utilise several specialty saw types to cut pipes, support structures, and other components.

Our essential gas fitting saws comprise:

- Hacksaws: Manually operated with changeable blades, ideal for cutting thin metal pipes up to a 50mm diameter and facilitating angled cuts.

- Copper Tube Cutters: Compact tools used one-handed to cleanly cut copper tubing without deforming walls or restricting flow.

- Reciprocating Saws: Featuring long, oscillating blades, these saws excel in creating passageways in walls and ceilings for pipework.

Each saw is chosen and used with meticulous care for cutting precision and safety. Accurate cuts guarantee secure fittings, prevent leaks, and ensure optimal gas flow as per AS/NZS 5601.

Specialized Gas Fitting Equipment

common tools, Padstow Plumbing technicians rely on specialty equipment designed explicitly for safe, efficient gas fitting work compliant with AS/NZS 5601 standards.

Key specialised instruments in our gas fitting arsenal include:

- Gas Leak Detectors: Handheld devices used to pinpoint even minute gas leaks quickly by sensing methane and other combustion gases. Vital for testing system integrity.

- Digital Manometers: Measure gas pressure levels to properly calibrate appliances and ensure optimal flow rates. Useful when pressure testing pipes.

- Flaring Tools: Create precisely shaped flares on copper tubing ends to enable secure fitting connections.

Such equipment is integral to our safe gas installation practices, with electronic leak detectors being key to confirming the integrity of all seals, thereby preventing accidents.

Advanced Leak Detection Technology

Detecting even minute gas leaks is crucial for ensuring the safety and integrity of any gas installation. At Padstow Plumbing, our technicians utilise high-sensitivity electronic leak detectors designed explicitly for locating methane, propane, and other combustible gases.

We use two primary types of gas leak detectors:

- Electronic Combustible Gas Detectors: Handheld devices containing sensors that detect trace leaks down to just a few PPM. Models feature audio and visual alerts that intensify as concentrations rise.

- Pipeline Tracing Gas Detectors: Designed to pinpoint the location of underground gas pipelines before excavations. Detect markers added to pipe contents without requiring flow.

Our specialists methodically scan all connections, joints, valves and other components after installations and repairs. Detectors swiftly signal small leaks, enabling prompt corrective sealing. This rigorous leak checking ensures full system integrity and prevents hazardous gas accumulation.

High-performance gas leak detectors are indispensable tools enabling our technicians to verify complete piping isolation and appliance safety. They give our clients confidence that their gas systems meet the most stringent quality and safety standards.

Flaring Tools

Flaring tools create precision-shaped flares on the open ends of metal gas pipes, allowing secure fitting connections. Our Padstow Plumbing technicians rely on quality flaring equipment to produce leak-proof seals that comply with AS/NZS 5601.

We operate both single and double flaring tools. Single flaring forms the end of an oxygen hose into a 45-degree angled cone to accept specially designed flared fittings. Double flaring takes this a step further by incorporating an additional inverted flare for enhanced leak resistance.

Proper flaring necessitates meticulous preparation, cleaning, measuring, and shaping of copper tube ends. Our specialists handle these tasks efficiently thanks to extensive training and experience.

Precision flaring creates superior gas pipe seals compared to standard welding hose fitting connections or compression fittings alone. Along with proper leak checks, quality flaring ensures durable, safe and legal appliance and pipe connections able to withstand pressure fluctuations.

Safety Considerations for Gas Fitting

Performing plumbing gas fitting work with the utmost gas safety is paramount. At Padstow Plumbing, we strictly follow all AS/NZS 5601 guidelines and regulations to ensure safety for all.

Our safe work method statement prescribes correct practices for handling tools and materials, inclusive of:

- Personal Protective Equipment (PPE): Our team dons fire-resistant attire, steel-toe boots, protective gloves, and eye and ear gear tailored to the task at hand.

- Electrical Safety: We implement anti-spark measures such as explosion-resistant lights and tools that are spark-proof in high-risk zones. Cords and plugs are maintained in good order.

- Fire Safety: Appropriate fire extinguishers are kept on-site. Technicians remain vigilant to potential ignition sources like cigarettes, hot works and static discharge risks.

- Gas Detectors: We utilise gas detectors before and during carrying out all gas fitting tasks to sniff out gas build up requiring immediate ventilation.

Adhering stringently to Australian Standards and staying vigilant allows us to promote safety for all involved. We continuously review policies and procedures to incorporate best practises into our gas fitting work.

Licensing and Professional Development

Gas fitting requires proper training and licencing to ensure work is carried out safely and to industry standards. In line with the NSW Gas Supply Act 1996, any person engaged in gas fitting must possess a valid gas work licence that corresponds with the specific gas type and task.

Licences are issued based on qualifications and experience. At Padstow Plumbing, all our gas technicians hold appropriate gas fitting licences issued by NSW Fair Trading after completing certified training courses covering:

- Safe work procedures for gas systems and appliances

- Compliance with AS/NZS 5601, AS/NZS 5149, and other relevant gas standards

- Selection, handling, and maintenance of specialised gas fitting tools/equipment

- Gas pipe sizing and materials specifications

- Leak testing and verification procedures

Our certified and licensed gas specialists possess the expertise to perform complex tasks, following stringent safety protocols. We invest heavily in ongoing training to stay current with codes and safety advancements in equipment and work methods.

Contact Padstow Plumbing for top-notch gas fitting services by qualified professionals at 1300 349 338 or [email protected].